PLASTICS

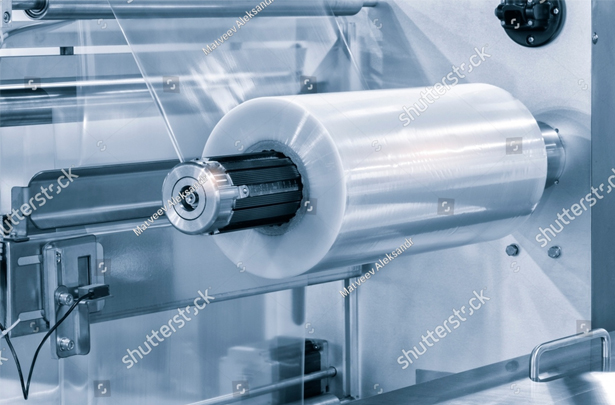

POLYETHYLENE (PE)

Polyethylene (PE) is a versatile thermoplastic polymer made from

ethylene monomers.

It is lightweight, durable, and resistant to chemicals.

It is a thermoplastic polymer characterized by its flexibility, low density, and translucence. Commonly used in packaging films, plastic bags, and containers, LDPE is resistant to moisture and chemicals. Its lightweight nature and ease of processing make it a popular choice in various industrial applications.

It is a strong, durable thermoplastic polymer known for its high strength-to-density ratio. Commonly used in containers, bottles, and piping, HDPE is resistant to impact, chemicals, and UV light. Its rigidity and versatility make it suitable for a wide range of applications in various industries.

It is a thermoplastic polymer characterized by its flexibility, toughness, and enhanced stretchability. It is produced using copolymerization of ethylene with alpha-olefins, resulting in a linear structure. LLDPE is commonly used in packaging films, grocery bags, and agricultural applications due to its excellent tensile strength and impact resistance.

POLYPROPYLENE (PP)

Polypropylene (PP) is a versatile thermoplastic polymer known for its light weight, durability, and resistance to chemicals.

Homopolypropylene is a type of polypropylene made from a single type of propylene monomer. It is characterized by high strength, rigidity, and excellent chemical resistance. Commonly used in automotive parts, packaging, and consumer goods, hPP is valued for its durability and ease of processing in various applications.

It is a type of polypropylene created by polymerizing propylene with other monomers, such as ethylene. This modification enhances its impact resistance, flexibility, and transparency compared to homopolypropylene. cPP is commonly used in applications like packaging, automotive components, and consumer products, offering improved performance and durability.

It is a type of polypropylene that incorporates ethylene in a random manner during polymerization. This structure enhances its clarity, flexibility, and impact resistance compared to homopolypropylene. rPP is often used in packaging, containers, and automotive parts, making it suitable for applications requiring durability and aesthetic appeal.

Polyvinyl Chloride (PVC) is a versatile thermoplastic polymer widely used in construction, plumbing, and electrical applications. It exists in two main forms.

It is a strong, durable thermoplastic widely used in construction and plumbing. Known for its rigidity and resistance to chemicals, uPVC is commonly used for pipes, window frames, and doors. Its weather resistance and low maintenance requirements make it a preferred choice for various applications.

It is a versatile thermoplastic known for its elasticity and adaptability. Commonly used in products like electrical cables, flooring, and inflatable items, flexible PVC offers excellent resistance to chemicals and UV light. Its ability to be easily processed and customised makes it suitable for diverse applications.

POLYETHYLENE TEREPHTHALATE (PET)

Polyethylene Terephthalate (PET) is a durable, lightweight thermoplastic widely used in packaging, textiles, and containers. Known for its excellent clarity, strength, and resistance to moisture, PET is commonly used for beverage bottles and food packaging. It is also recyclable, making it an environmentally friendly choice for various applications.

+971 52 253 96 94

+971 52 253 96 94